High Heat Resistant FPCs

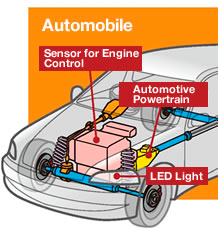

For LED Light

Automotive Sensor

We developed a highly heat resistant FPC that ensures long-term reliability in environments of 150℃ (Maximum: 175℃) by enhancing the heat resistance of the adhesive layer of the insulation film (coverlay) to withstand high temperatures of 100℃ or over, which is required in automotive and LED light applications. We enabled smaller sizes and lighter weights by enhancing the design freedom on the assumption that these products can be used for the transmission cable wiring of automotive powertrains and light fixtures.

Features

Feature 1

Long-term Heat Resistant Reliability Ensured under High Temperatures

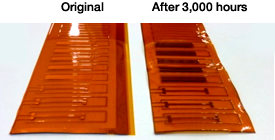

This FPC can be used at high temperatures because we ensured adequate bonding strength (JPCA Spec. 3.4 N/cm) of the coverlay adhesive in 3,000 hours of endurance tests at 150℃ in air and in oil.

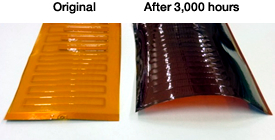

【Conventional FPC】

Marked discoloration of adhesive, warping

Marked discoloration of adhesive, warping

【Our Developed FPC】

Almost no discoloration or warping

Almost no discoloration or warping

Feature 2

Long-term Reliability Ensured at High Temperature and Humidity (85℃ 85%RH)

This FPC meets the enhanced reliability and endurance of electronics appliances as the bonding strength (JPCA Spec. 3.4 N/cm) of the coverlay adhesive has been improved to withstand 3,000 hours (at 85℃ and 85%RH ), compared to the 1,000 hours for conventional material.

Applications

Automotive Power-trains, LED Lights etc.

Inquiries about our products

Please feel free to contact us.

A member of our staff will contact you shortly.

A member of our staff will contact you shortly.