Ultra-fine-pitch FPCs

Features

Sumitomo Electric Printed Circuits works in cooperation with the R&D Group of Sumitomo Electric  to develop ultra-fine-pitch FPCs using a number of its proprietary technologies and mass-produces many of them. This includes not only the minimization of line and space (L/S) sizes as a high-density wiring technology but also advanced technology for producing high-aspect-ratio circuits.

to develop ultra-fine-pitch FPCs using a number of its proprietary technologies and mass-produces many of them. This includes not only the minimization of line and space (L/S) sizes as a high-density wiring technology but also advanced technology for producing high-aspect-ratio circuits.

to develop ultra-fine-pitch FPCs using a number of its proprietary technologies and mass-produces many of them. This includes not only the minimization of line and space (L/S) sizes as a high-density wiring technology but also advanced technology for producing high-aspect-ratio circuits.

to develop ultra-fine-pitch FPCs using a number of its proprietary technologies and mass-produces many of them. This includes not only the minimization of line and space (L/S) sizes as a high-density wiring technology but also advanced technology for producing high-aspect-ratio circuits.

Strengths of our fine-pitch FPCs

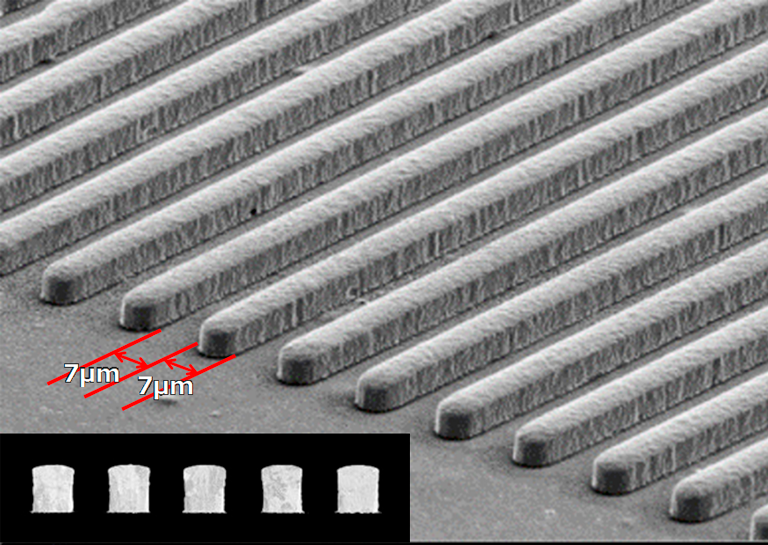

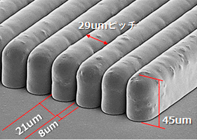

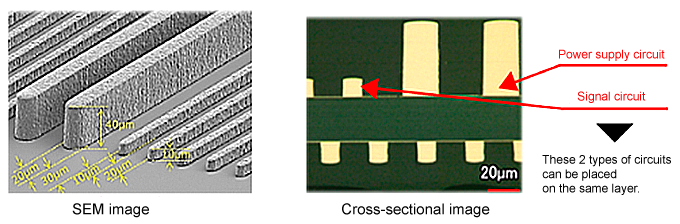

Fine-pitch wiring requires highly advanced circuit patterning technology. Sumitomo Electric Printed Circuits has evolved its proprietary technology in each manufacturing process and has succeeded in implementing a L/S of 20 µm/20 µm for mass-produced products, 15 µm/15 µm for prototypes, and 7 µm/7 µm for newly developed products. At the same time, extremely advanced technology is required to achieve a high aspect ratio, or an increased line height with narrow line spacing maintained. We have established circuit production technology for high-density, high-aspect-ratio FPCs, with line spacing (the S in L/S) of 10 µm or less and a line height of 50 µm or more.

Scanning electron microscope (SEM) image of ultra-fine-pitch FPC

Newly developed product ( L/S=7 µm/7 µm )

SEM image of high-density, high-aspect-ratio FPC

SEM image

Enlarged section

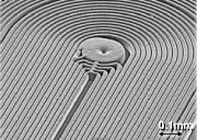

Planar coils

are products that utilize high-density, high-aspect-ratio fine-pitch circuit production technology.

We provide the optimal circuit and electrical characteristics, meeting your needs by using simulation technology based on CAE analysis.

Applied technology

We are also developing a technology to create tall and short fine-pitch circuits on the same layer. This technology will make it possible to form both power supply circuits and high-density signal circuits on the same layer.

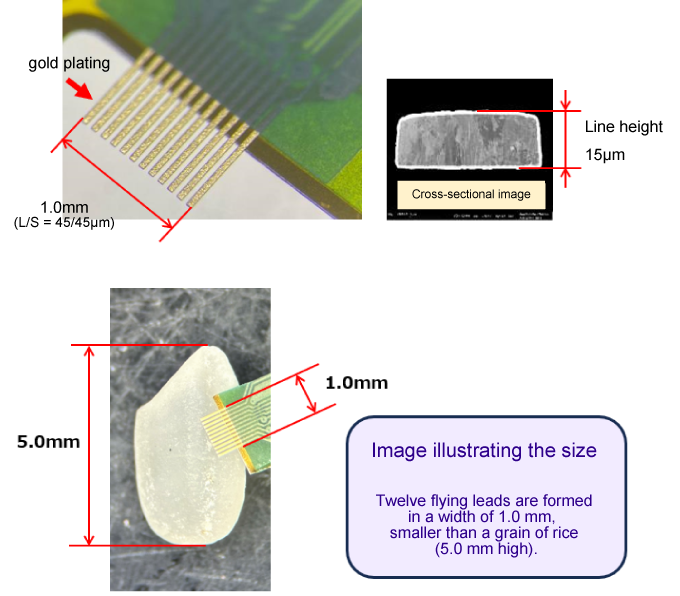

Compared to conventional flying leads, we have established our own processing technology that enables the entire flying lead block, including lead tips, to be covered with gold plating. Moreover, we are also mass-producing these products.

Expectations and outlook for fine-pitch FPCs

1.Use as wiring materials

By evolving from conventional FPCs to fine-pitch FPCs, the following new applications and benefits can be expected as wiring materials.

| Expected benefits | Features | Replacement with fine-pitch FPC |

|---|---|---|

| Narrow and thin wiring | Space and weight saving | Cable >>> Fine-pitch FPC |

| High-density mounting of components | Integration into module | PCB + Cable >>> Fine-pitch FPC |

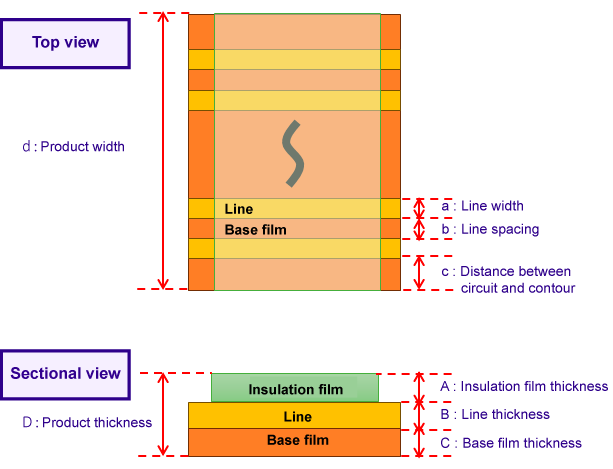

FPC vs. FFC: Size comparison of narrow-wiring products * Reference values (preconditions: single-sided wiring, 40 wires)

| FPC | Comparison | FFC | ||

|---|---|---|---|---|

| a | Line width | 0.015mm | < | 0.15mm |

| b | Line spacing | 0.015mm | < | 0.15mm |

| c | Distance between circuit and contour | 0.20mm | < | 0.75mm |

| d | Product width | 1.6mm | < | 13.5mm |

| A | Insulation film thickness | 0.020mm | < | 0.050mm |

| B | Line thickness | 0.008mm | < | 0.025mm |

| C | Base film thickness | 0.012mm | < | 0.025mm |

| D | Product thickness | 0.04mm | < | 0.10mm |

FPC:Flexible printed circuits

FFC:Flexible flat cable

FFC:Flexible flat cable

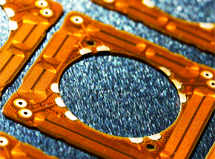

2.Use as functional components

FPCs have traditionally been used primarily as wiring materials, but by producing a fine-pitch circuit in a spiral shape, they can also be used as functional components (planar coils) that generate magnetic force. We have already been mass-producing them.

(An example of a planar coil)

Sumitomo Electric Printed Circuits provides ultra-fine-pitch FPCs that are compatible with electronic device terminals that are continually evolving, becoming smaller and more functional with the times. For example, we will bring about innovation in fields where miniaturization and high functionality are required, such as wearable devices, sensing modules, high-resolution displays, robotics, medical devices, and aviation/space.

Inquiries about our products

Please feel free to contact us.

A member of our staff will contact you shortly.

A member of our staff will contact you shortly.