Polymer Materials

The polymer materials technologies developed in SEI group are put into our FPC.

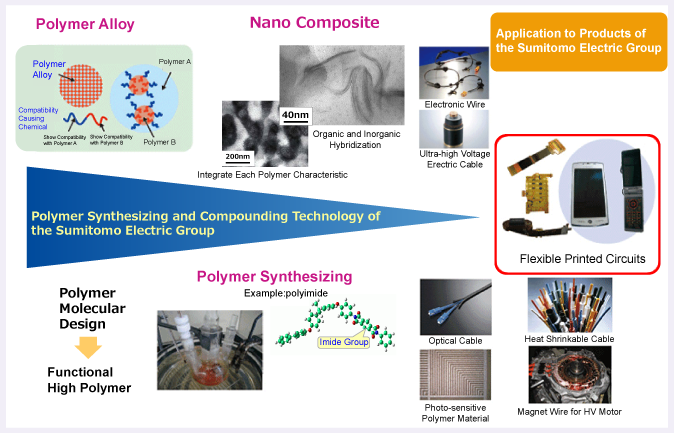

SEI group has been engaged in enhancing the high polymer synthesizing technology, nano-dispersion technology, polymer alloy technology and the compounding technology in order to keep ahead of the time, which target is various kinds of needs like the flame-resistance, heat-resistance and environmental resistance properties, etc. By covering the complete process of material development to application to FPC products based on these core technologies, we are creating products that meet customer needs in every details.

Features

Polymer Synthesis

Polymer Synthesis

In order to respond to various property requirements for FPCs, we are developing the high polymers from the stage of materials like molecular design and synthesis. For example, we have developed an ultra-high heat resistant FPC that had not been obtained before by synthesizing a high polymer of easy adhesion and easy shape from a kind of polyimide resin.

Nano Composite

Dispersion of Organic and Inorganic Nano-particles

We have core technology for finely dispersing organic or inorganic particles into polymers. For example, we have developed adhesives that are sought for LED lights and other future applications, which have both high thermal conductivity and high adhesive strength, by dispersing fillers of high thermal conductivity into adhesive finely.

Polymer Alloy

Polymer Alloying

Polymer alloying is a technology that brings out the desired properties of respective components and creates materials which have multiple characteristics by compounding and minutely dispersing high polymers which normally can not be compounded, as if making an alloy. We are using this technology to develop products, such as high heat resistant FPCs which have high adhesive performance to substrate, conductor and stiffener, etc.

Adhesive Compounding

Various types of insulation adhesive are used to insulate the Cu circuits of FPCs. These adhesives require various properties, such as flame resistance and heat resistance, besides bonding strength. Moreover, in recent years, it has become mandatory to meet environmental requirements such as the RoHS Directive and halogen free requirements. We are fully utilizing our know-how of various organic or inorganic adhesive compounding in order to deliver these properties, and market FPC products that satisfy customer needs.

Total Production of FPC Materials

We can produce FPCs completely in-house from the raw materials of insulation adhesives, formation into sheets and application to FPC products. By controlling quality through the entire production process, we are making and marketing FPCs that satisfy the high cleanliness requirements of hard disk drives. Moreover, we are developing products that meet customer needs in every detail by handling everything in-house from the development of raw materials.