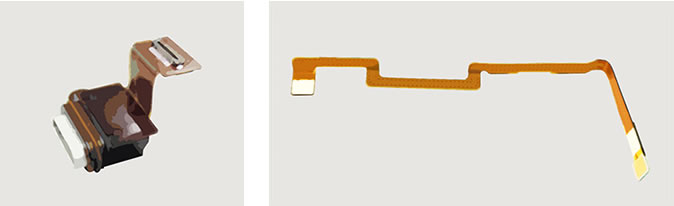

Shape Keeping FPC

Manufacturers wish assembling FPCs could be more easily assembled into outer cases because of slimmer and smaller sized electronic appliances. We developed an FPC that retains a required shape after bending through our efforts with materials and processing methods. As a result, we can propose to customers improvements in assembly work and quality. We expect to reduce processing cost further by introducing automatic parts mounting.

Features

Improvement in Assembly Work

As we supply FPCs in the required shape, customers do not need to implement secondary processes such as bending, which leads to improved efficiency in assembly work. We further anticipate cost reductions via automated component mounting in the future.

Improvement in Assembly Quality

FPCs run into quality problems, such as wrinkles and breaking when bent because they are thin and difficult to handle. This FPC eliminates any handling by customers by our implementing bending beforehand, which will lead to a higher yield from assembly operations.

Material Designed Superior for Keeping Shape

Polyimide film that is normally used for FPCs has a strong restorative force after bending, so it does not retain its shape after bending. We have succeeded in developing a shape-retaining FPC and a simple bending process by selecting insulation film (LCP film and flexible solder resist) of low restorative force.

Applications

Mobile Phones, Digital Cameras, Liquid Crystal Displays for Mobile Device