High Density Component Mounting

0.4mm Pitch BGA

0.35mm Pitch Connector

We are mounting various electronic components on FPCs with RoHS Directive-compliant and halogen-free respondent solder such as SAC305. We can also mount electronic components having a low heat resistance of 200℃ or below by way of ACF connection or low melting point solder. We can also supply products where FPCs are connected to rigid boards or other FPCs with ACF. These products used to be connected via connectors, etc., but we are developing ACF’s technology as a response to customer demands for low height connections. Moreover, we can conduct various functional inspections of circuit boards where such electronic components are mounted.

Features

Component Mounting

We are mounting electronic components of various sizes to the same FPC, including small components such as 0402 size chips, and 0.35 mm pitch connectors, fine pitched parts, and large components such as vibrators, SD card sockets, USB connectors, jack connectors, etc. We are using originally developed solder paste to support small components of low-height, etc. We are also applying coatings to strengthen electronic component connections so that their mounted FPCs can be pasted to various shaped outer casings, as well as applying resin coatings that possess waterproofing property.

Low Temperature Mounting, ACF Connections

For LEDs, camera parts or PET base material of low heat resistance, we are mounting electronics components using low melting point solder and ACF. We choose the best connection method for the heat resistance of such components and materials.

ACF Connection

(FPC-FPC、FPC-Camera、FPC-Flash FPC-LED etc.)

Mounting with Low

Temperature Molten Solder

Inspections

We conduct functional inspections of FPCs mounted with electronic components in line with customer needs. We can inspect key functional parts such as cameras, microphones and touch sensors in-house.

Image Inspection

(Camera Parts)

Sound Inspection

(Microphone and Speaker Parts)

Capacitance Inspection

(Touch Sensor)

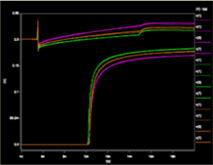

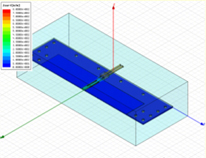

Simulation of high frequency performance

We are responding to the FPC design which meets customer needs through the actual measurement of FPC impedance and transmission characteristics, and the advanced analysis technology.

Transmission characteristic prediction by the circuit simulator

Measured value(500Mbps)

Simulated value(H-Spice)

Circuit model based on TDR/TDT

Calculation and analysis by the electromagnetic field simulator

FPC impedance calculation

Feedback current distribution